In the world of electronics and contemporary innovation, the relevance of printed circuit boards (PCBs) can not be overemphasized. A PCB, commonly referred to as a circuit board, gives the important structure for connecting numerous electronic parts through conductive tracks etched onto non-conductive substrates. Among the lots of kinds of PCBs, the rigid-flex circuit boards stand out as a remarkable development.

The production of PCBs, particularly in high-density interconnect (HDI) arrangements, has actually progressed as the need for smaller sized, much faster, and more efficient electronics increases. HDI PCBs incorporate finer lines and rooms, along with smaller sized vias, which allow for greater component density. This is particularly important in today's fast-paced tech landscape where performance improvements are continuously sought. To manufacture these advanced boards, companies often employ advanced strategies such as microvia modern technology, which entails developing really tiny vias with laser drilling techniques. The benefits of microvias include increased signal speed and reduced electromagnetic disturbance, thereby enhancing the total capability of the electronic gadgets they support.

Collective ventures with printed circuit manufacturers are vital in ensuring that PCB styles transition smoothly from theoretical stages to actual items. Printed circuit board assembly (PCBA) becomes a crucial action in the process where various elements are soldered onto the PCB in exact setups to ensure optimal operation.

Quick turn-around PCB prototyping services have actually obtained appeal as businesses aim to bring their products to market quickly. This active manufacturing strategy permits companies to examine and verify their styles before dedicating to full production runs. Such prototyping is vital in lowering time-to-market and allows for iterative enhancements based on initial testing outcomes. Suppliers supply flexible alternatives for both high-volume and low-volume orders to fit diverse manufacturing needs. Furthermore, with the raising schedule of fast-turn PCB services, the obstacles to prototype growth have actually been substantially reduced, allowing a setting of innovation.

Flexible printed circuit boards (FPCBs) are an additional remarkable group that has gathered attention because of their unique abilities. These boards are developed to be ultra-thin and light-weight, providing the ability to bend, fold up, or twist without compromising efficiency. This adaptability makes them a perfect option for applications in numerous areas, including consumer electronics, auto, and medical gadgets. FPCBs can additionally help improve assembly procedures, as their design allows for a more small kind element, which frequently leads to less link factors and potential failure settings.

Thermal monitoring, for circumstances, plays an important role in PCB design, specifically in electronic products that run under high tons. Engineers have to think about products with great thermal conductivity, such as heavy copper PCBs, which help dissipate warmth efficiently.

Understanding about various aspects such as circuit card assembly, which includes the process of soldering components onto a PCB, can significantly impact the end product's quality. Additionally, utilizing devices and software program designed for PCB layout and simulation can drastically improve the design process, enabling developers to rapidly change prototypes based on screening outcomes.

Variations in PCB types such as 2-layer, 4-layer, and multi-layer boards are each suited to specific applications based upon their intricacy and the variety of elements that need to be integrated. Four-layer PCBs provide raised transmitting capacities, vital for much more sophisticated electronics. These boards aid in managing signal honesty and supply sufficient space to route traces better, making certain more reputable performance in every little thing from smartphones to intricate industrial tools.

Contract PCB assembly services have come to be an important source for companies lacking the internal capabilities to handle intricate assembly processes. These services usually include thorough support ranging from design consultation to full-blown production, giving companies with more info the adaptability they need to satisfy differing demands. By partnering with well established manufacturers, organizations can leverage expertise in areas such as HDI designs, microvias, and multilayer PCBs, therefore expanding their product offerings click here without spending greatly in tools and labor.

Choosing the ideal products for PCB production is important, and factors to consider usually include the environmental requirements suitable to their use, consisting of UL ratings, such as 94V-0, which relates to terminate retardancy. Manufacturers require to stay educated about conformity policies to guarantee that their items fulfill safety requirements while likewise doing ideally in their desired application environments.

The integration of radio frequency (RF) technology into PCBs is another area seeing enhanced significance, especially with the increase of wireless communication devices. RF PCBs have to be meticulously made, with factors to consider for insusceptibility control and decreased signal loss as a result of the high regularities included. This specialization calls for expertise of RF circuit design and might include comprehensive electromagnetic simulations as designers function to accomplish optimal functionality in portable types.

As technology continues to advance, manufacturers are progressively adopting automation and advanced fabrication processes to boost effectiveness. Technologies such as automated optical inspection (AOI) and surface area install modern technology (SMT) are now standard techniques, enabling high-speed assembly and regular quality assurance. Innovations in PCB manufacturing likewise encompass brand-new materials and methods, such as using embedded modern technology where elements are ingrained directly within the layers of the PCB, additionally conserving area and improving efficiency.

In conclusion, the printed circuit card sector continually adapts to altering demands and technical developments, showing the vibrant landscape of electronics. Whether through PCBA, flexible circuits, or fast-turn prototypes, the procedures, designs, and materials connected with PCBs are vital fit the future of electronic gadgets. Manufacturers that stay at the leading edge of these developments not only improve their affordable side yet additionally enable the growth and development of advanced modern technologies that define modern life. With the ever-increasing intricacy of circuits and the demand for effective, high-performance options, the PCB sector continues to be a foundation of technological progress, driving the method we communicate with gadgets and eventually linking our physical and digital worlds.

Kel Mitchell Then & Now!

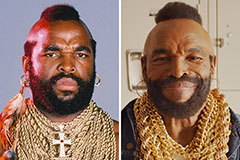

Kel Mitchell Then & Now! Mr. T Then & Now!

Mr. T Then & Now! Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!